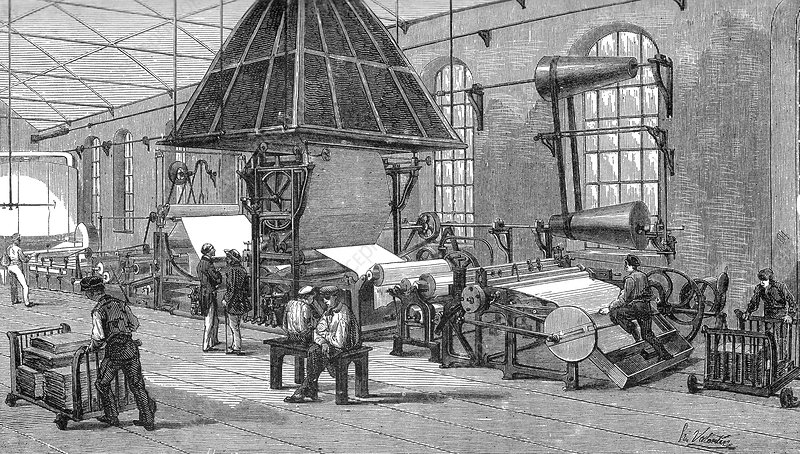

The paper supply chain turmoil has come for Local Culture. Once the order of paper arrives, the magazines will be printed and mailed to subscribers. They are hoping a new shipment arrives next week, but apparently lots of large printers are now stockpiling paper, which means there is less for the little guy. That would include us.

Update: Our intrepid printer was able to find a different source, and copies are flying off the printer now as I type. They should begin going in the mail tomorrow. Apologies for the false alarm.